O2 Technologies empowers automotive manufacturers, suppliers, and mobility service providers to accelerate digital transformation and stay ahead in an era of connected, autonomous, and electric vehicles. Our technology-driven solutions enhance design efficiency, production agility, customer experience, and aftersales operations—helping automotive businesses innovate faster and operate smarter.

At O2 Technologies, we combine deep automotive domain experience with advanced digital technologies to reshape the way vehicles are designed, manufactured, and supported. Our expertise spans connected vehicle platforms, AI-driven manufacturing analytics, digital twin simulation, IoT-enabled maintenance, supply chain optimization, and cloud-based enterprise systems. We help automotive enterprises modernize operations with data-driven insights, predictive maintenance, and real-time production visibility. Through AI and machine learning, we enable smarter demand forecasting, automated quality control, and customer personalization—reducing downtime and improving performance across the value chain. Our cloud and edge computing solutions ensure seamless connectivity between vehicles, factories, and customers, while automation frameworks streamline engineering and logistics. From enhancing R&D collaboration and manufacturing intelligence to building connected customer ecosystems, O2 Technologies drives innovation and resilience in the automotive industry—powering a smarter, sustainable, and more connected future of mobility.

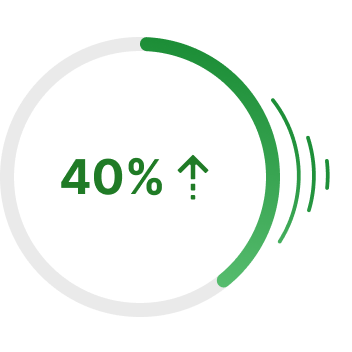

Client Challenge: A global automotive manufacturer faced inefficiencies in its production lines due to manual monitoring, delayed reporting, and unplanned equipment downtime.

O2 Tech Solution: Implemented an IoT-enabled smart factory system with real-time equipment tracking, AI-driven predictive maintenance, and automated production analytics dashboards.

Impact: Increased production efficiency by 40%, reduced downtime by 30%, and improved overall equipment effectiveness (OEE) across manufacturing units.

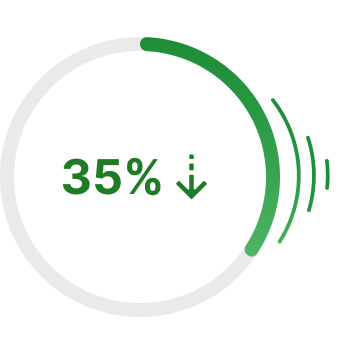

Client Challenge: A leading automotive OEM struggled with long development cycles and high prototyping costs for new vehicle models.

O2 Tech Solution:Deployed a digital twin platform that simulated vehicle performance, design variations, and component durability using real-time sensor and CAD data.

Impact:Reduced prototyping costs by 35%, accelerated design validation, and shortened time-to-market for new vehicle models.

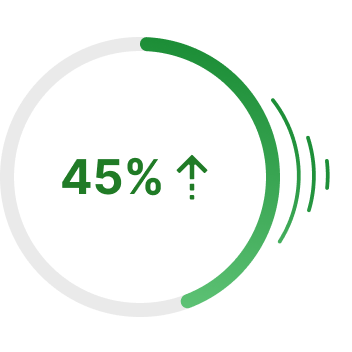

Client Challenge: An automotive brand sought to deliver personalized, data-driven customer experiences but lacked real-time insights into vehicle usage and driver behavior.

O2 Tech Solution: Built a cloud-based connected vehicle analytics platform that gathered telematics data to enable predictive maintenance alerts, driver behavior insights, and in-app personalization.

Impact: Boosted customer satisfaction scores by 45%, reduced maintenance-related complaints, and increased service retention rates across dealerships.

Hospital chain faced delays in treatment due to scattered patient information across multiple systems and departments.

A large healthcare provider was burdened with manual appointment scheduling, billing, and bed management, causing workflow bottlenecks.